Regardless of how you choose to look at it, home automation brings a wide range of benefits, making life more convenient, efficient, and secure. For starters, automating household systems can significantly reduce energy consumption and utility costs. Smart thermostats, lighting, and appliances can optimize their operation based on usage patterns, ensuring no energy is wasted. This allows homeowners to save money while minimizing their environmental footprint.

Regardless of how you choose to look at it, home automation brings a wide range of benefits, making life more convenient, efficient, and secure. For starters, automating household systems can significantly reduce energy consumption and utility costs. Smart thermostats, lighting, and appliances can optimize their operation based on usage patterns, ensuring no energy is wasted. This allows homeowners to save money while minimizing their environmental footprint.

Home automation also enhances safety and security. Smart devices like automated locks, motion detectors, and surveillance cameras provide real-time alerts and remote monitoring, offering peace of mind. Additionally, automated systems can simplify daily routines, such as scheduling lights, managing climate control, or even preparing coffee in the morning.

There are three major sources for actuation power in home automation: pneumatic, hydraulic, and electric. This article explores the role of electric actuators in home automation. These actuators are pivotal in powering smart devices, enabling seamless integration and improved functionality, making them a cornerstone of modern home automation systems.

How Linear Actuators Operate

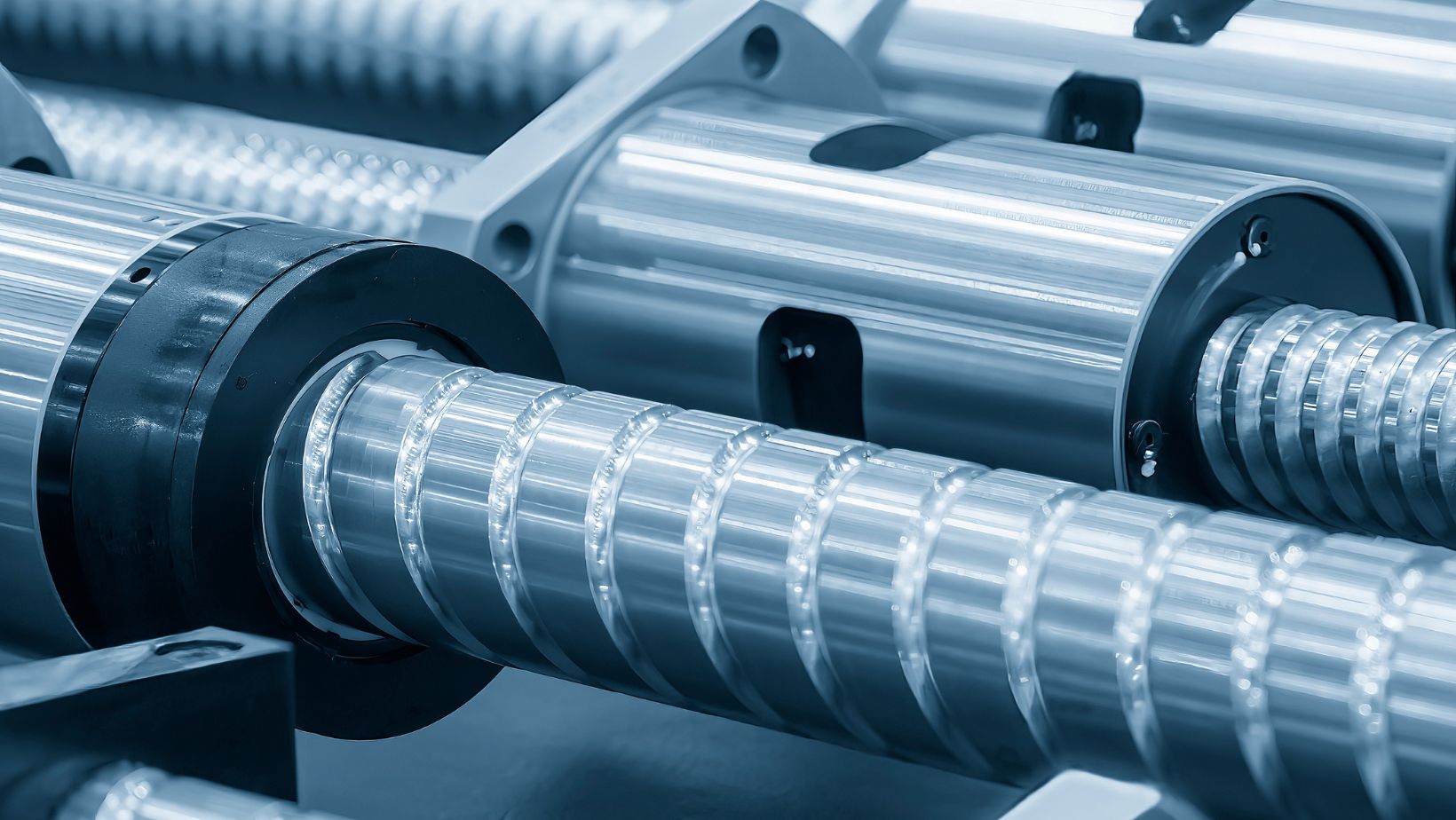

A linear actuator is a device that converts energy, whether electric, hydraulic, pneumatic, or otherwise, into mechanical motion that can be precisely controlled. The type and amount of energy required depend on both the energy source and the actuator’s intended function. For example, electric and piezoelectric actuators operate using electric current or voltage, while hydraulic actuators rely on incompressible liquids, and pneumatic actuators use air. Regardless of the input, the output is always mechanical energy.

Though actuators may not be as commonly discussed as artificial intelligence or machine learning, they are indispensable in modern technology. Their role is foundational in various applications, often determining whether a device can function as intended. In industrial mechatronic systems, for instance, actuators enable movement in robotic arms when powered by an electric input. In vehicles, actuators are critical to engine control systems, where they regulate air flaps for optimizing torque, power output, idle speed, and fuel efficiency to ensure ideal combustion.

Actuators also play a significant role in everyday home applications, seamlessly integrating with modern conveniences. They enable the operation of consoles or cabinets that house televisions, allowing them to open or close at the touch of a button. Similarly, they are integral to TV and table lifts, giving users the ability to adjust these features effortlessly through electric switches. Recliners with movable headrests or footrests also rely on actuators, adding comfort and functionality. Moreover, home automation systems, such as those that intuitively close window blinds based on incoming sunlight, are made possible by actuators. Essentially, wherever mechanical movement is required, actuators are the driving force, underscoring their boundless applications in both industrial and domestic settings.

To understand how a linear actuator works, it is essential to examine the components that enable its functionality:

- Power Source: The energy input necessary to drive the actuator comes from a power source. In industrial systems, this is often electric or fluid-based, such as hydraulic fluid or compressed air.

- Power Converter: A power converter transfers energy from the source to the actuator, aligning with the parameters set by the controller. Examples in industrial settings include hydraulic proportional valves and electrical inverters.

- Actuator: This is the core device that transforms the supplied energy into mechanical force, enabling movement.

- Mechanical Load: The actuator’s mechanical energy drives a mechanical load, which is the system or device requiring movement—such as a robotic arm or an adjustable home appliance.

- Controller: A controller ensures the actuator functions correctly, managing the input quantities and operational parameters established by an operator.

From operating large-scale industrial machinery to enhancing everyday comfort at home, actuators are an indispensable part of the technological landscape, bridging the gap between energy and motion in countless applications.

What is an Electric Linear Actuator and How Does It Work?

Electric linear actuators, as the name suggests, convert electrical energy into straight-line motion. These devices are designed to enable movements such as pulling, pushing, lifting, ejecting, clamping, blocking, or descending, making them essential in a wide range of applications. Their operation relies on the back-and-forth motion of a piston, driven by electrical signals.

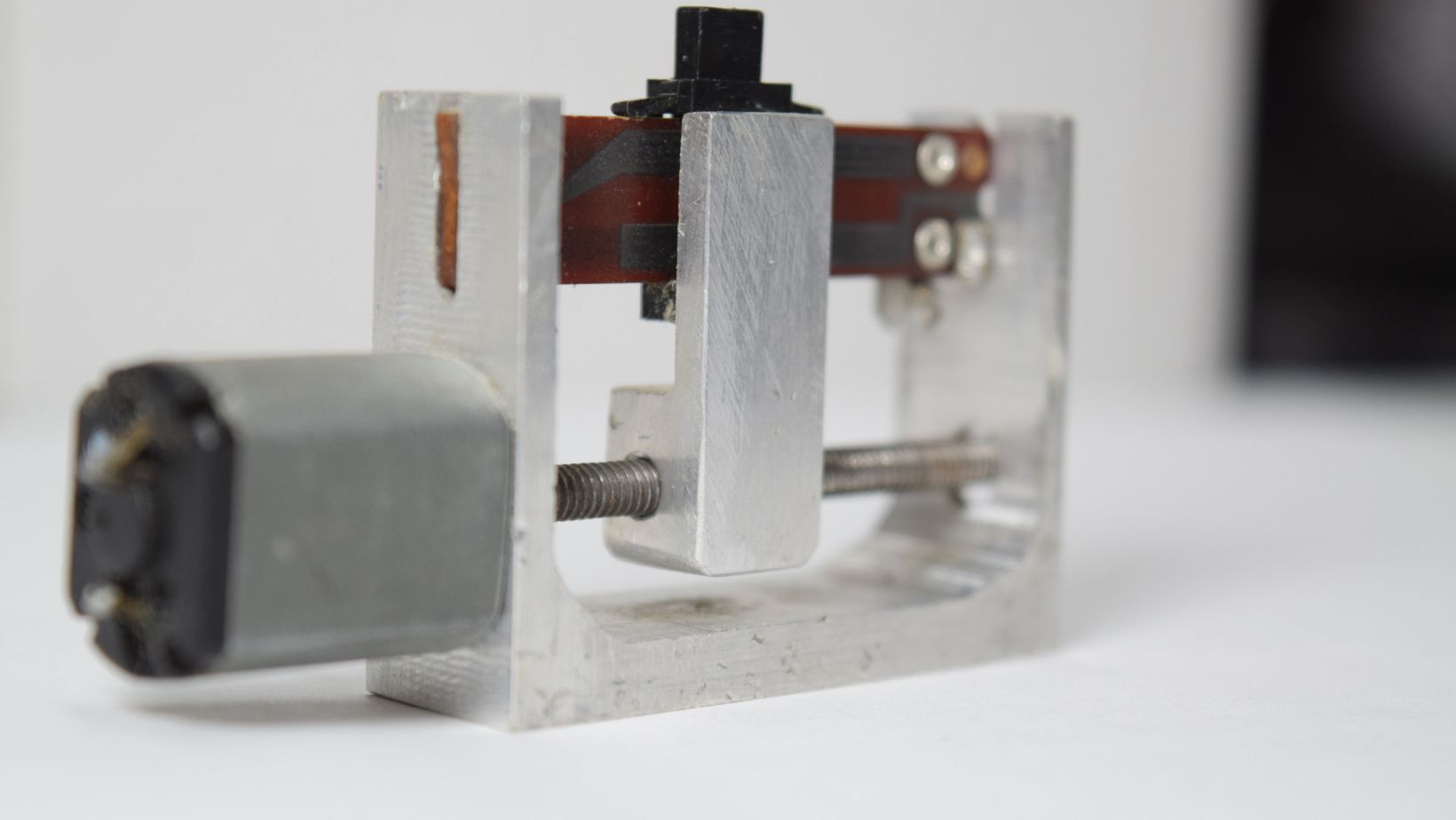

The functionality of an electric actuator begins with a motor, which generates high-speed rotational motion. A gearbox then reduces this rotational speed while increasing torque. This torque is transferred to a lead screw, creating the linear motion required to move a shaft or drive nut. In many cases, a 12V DC motor powers the actuator, though motors with other voltage specifications are also available. To reverse the direction of motion, the polarity of the motor’s connection to the power source can be switched.

Manufacturers design linear actuators with varying stroke lengths by adjusting the shaft’s length to meet specific requirements. Additionally, different gear configurations allow for varying speed options. It’s important to note that as the screw turns faster, the available force decreases. To ensure smooth operation, a built-in switch within the actuator shaft stops the screw when it reaches the top or bottom of its stroke. At these points, the switch automatically cuts power to the motor, preventing overextension or damage.

With their versatility and precision, electric linear actuators are an indispensable component in many modern systems, providing reliable and efficient linear motion.

Choosing the Appropriate Linear Actuator for Your Needs

Linear actuators play a crucial role in various applications, but not all are created equal. Selecting the right actuator for your needs starts with understanding the specific requirements of your project. The first step is to determine the type of motion required. If your application involves straight-line movement, a linear actuator is the best choice, as it provides the mechanical force to move objects in a straight path. On the other hand, rotary actuators are better suited for tasks that involve circular motion. Knowing the movement type ensures that the actuator aligns with your project’s demands.

Another important factor to consider is the energy input. While electric actuators are widely used for their sophistication and versatility, they may not be the right fit for every situation. For projects that lack access to electrical power or require higher force output, hydraulic or pneumatic actuators might be a better alternative. Precision is also key when selecting an actuator. Heavy-duty actuators are excellent for rough environments, but they may lack the finesse needed for tasks like packaging, where consistent and precise movements are required.