Machining tools are transforming the way automotive repairs are conducted, offering enhanced precision and efficiency. As both do-it-yourself enthusiasts and professional mechanics increasingly rely on these tools, understanding their role in vehicle maintenance becomes crucial. Mastering the selection and use of these tools not only improves repair quality but also ensures safety and durability.

The integration of machining expertise in automotive repair is indispensable for achieving accurate and reliable results. Whether you are a seasoned mechanic or a DIY hobbyist, precise cutting methods significantly impact the quality of your work. As machining continues to advance, it is important to stay informed about the choosing the right end mill and tools available in the industry.

Fundamental Machining Principles for Vehicle Maintenance

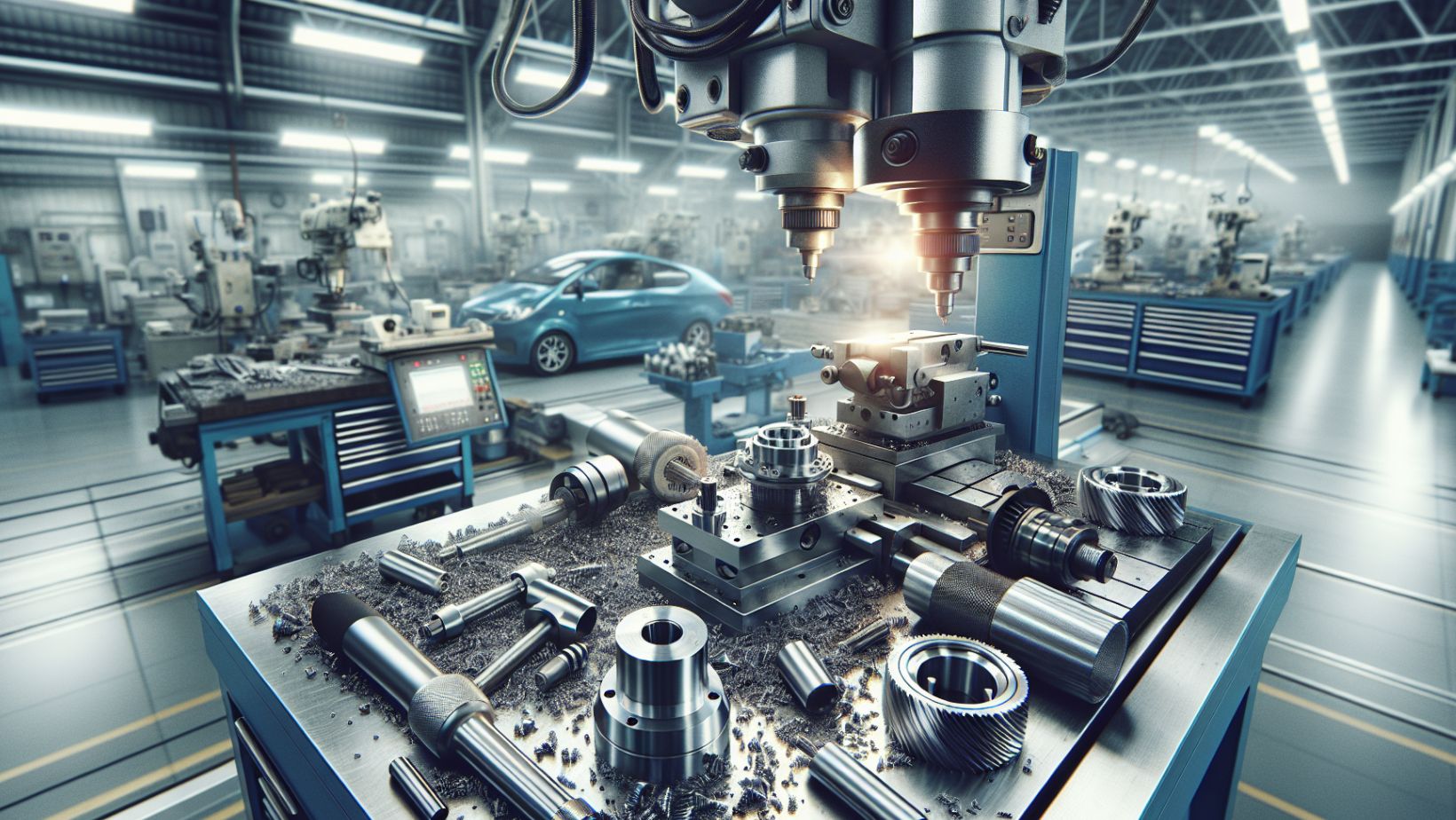

The relationship between metalwork and repair accuracy is at the heart of effective automotive maintenance. Machining operations such as drilling, milling, and turning play a critical role in crafting components that fit perfectly with existing systems. To achieve consistent results, it is essential to understand these basic principles and how they apply to different types of vehicle repairs.

Incorporating machining into your repair projects involves recognizing the importance of choosing the right end mill. This decision directly affects the durability and finish of your work, particularly when working with varied materials like aluminum or steel. Ensuring that you select the proper tool for each task can greatly influence the overall success of your projects.

Safety precautions around workshop machinery cannot be overlooked. Proper training and vigilance help prevent accidents and ensure a safe working environment. By adhering to recommended safety guidelines, you can confidently operate machinery while minimizing risks associated with high-speed metalworking operations.

Importance of the Correct Cutting Tools

The outcomes of your automotive projects are largely determined by the cutting tools you choose. Different tools yield varied results in terms of durability and finish, making it vital to match each tool to its specific application. For instance, when working with materials like aluminum or steel, it’s important to select tools that complement these properties to achieve optimal results.

The necessity of choosing the right end mill cannot be overstated when striving for consistent and reliable outcomes. This crucial choice ensures that your repairs maintain structural integrity while delivering a smooth finish. By evaluating material constraints carefully, you can enhance both the efficiency and quality of your work.

Beyond just selecting the right tools, maintaining them is equally important. Regular inspection and replacement as needed will prevent unnecessary wear and tear on both the tools themselves and the components they are used on. A well-maintained toolkit is foundational to producing high-quality automotive repairs consistently.

Preparing the Work Area

A well-organized work area is fundamental to successful machining operations. Ensuring that all tools and components are laid out properly facilitates smooth workflow and minimizes errors during repairs. This preparation includes setting up stable fixtures that support accurate operations without risking worker safety.

Checking alignment and calibration before beginning any project is crucial for precision in machining tasks. Taking these preparatory steps helps avoid costly mistakes that could compromise both the vehicle’s integrity and your own safety during repairs.

Ensuring a clean workspace free from obstructions also contributes to effective machining practices. With everything in place, you can focus on executing repairs with greater confidence and efficiency.

Ideal Practices When Working With Machining Equipment

Optimizing feed rates and speeds is essential for reducing tool wear while maintaining efficient operations. By understanding these dynamics, you can prolong tool life while achieving desired results with minimal friction.

Lubrication plays a significant role in smooth operation; using appropriate lubricants reduces heat build-up and minimizes friction between moving parts. This practice not only protects your tools but also enhances the overall quality of your automotive repairs.

Monitoring tool condition regularly prevents damage to automotive components by ensuring that each tool performs at its best capacity throughout every project stage. By adopting these best practices, you can extend tool life while ensuring consistent top-notch repair outcomes.