Variable Frequency Drives (VFDs) are critical components in modern industrial settings. They control the speed of motors, optimize energy usage, and provide enhanced operational control. However, like any electronic device, VFDs are subject to wear and tear, failures, and other issues that can disrupt industrial processes. Repairing a VFD rather than replacing it can offer significant cost savings, but it requires a well-thought-out strategy. In this article, we will explore cost-effective VFD repair strategies that can help industrial operators keep their systems running efficiently without breaking the bank.

Understanding VFDs and Their Importance

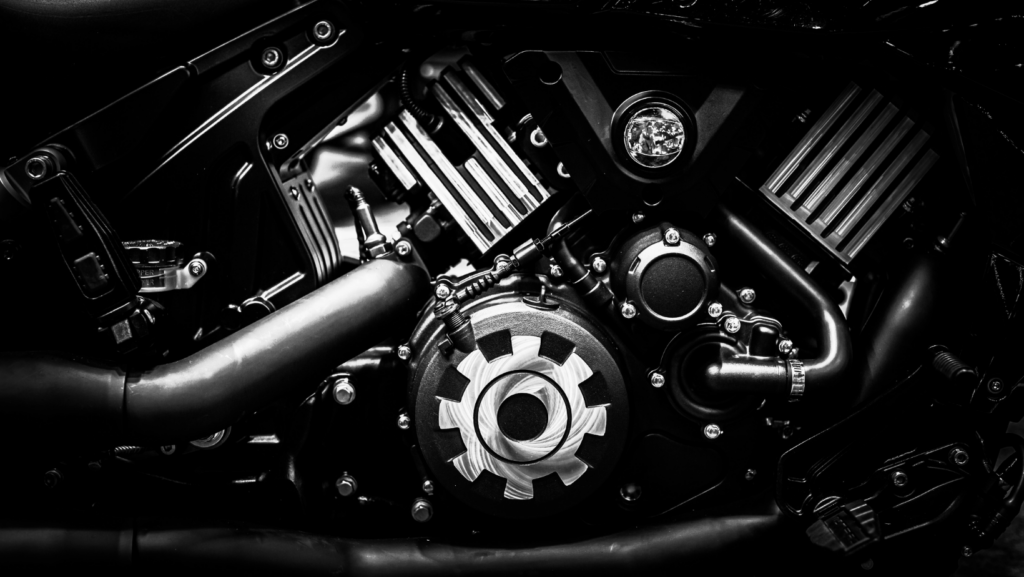

Before diving into the repair strategies, it is essential to understand the role VFDs play in industrial applications. VFDs are electronic devices that control the speed and torque of electric motors by adjusting the frequency and voltage supplied to them. This ability to control motor speed provides numerous benefits, including energy savings, extended motor life, and improved process control.

VFDs are used in a variety of industries, including manufacturing, energy, HVAC, and transportation. They are employed in a wide range of applications such as pumps, fans, conveyors, and compressors. Given their vital role in many industrial processes, a malfunctioning VFD can lead to significant downtime and productivity losses.

Common VFD Failures and Their Causes

To implement cost-effective VFD repair strategies, it’s important to identify common causes of failure. Understanding these causes allows operators to not only address repairs but also take preventative measures to avoid recurring issues.

Overheating

One of the most common causes of VFD failure is overheating. VFDs generate a lot of heat during operation, and if not properly managed, this heat can damage internal components. Overheating can be caused by poor ventilation, clogged filters, or faulty cooling fans.

Electrical Component Failure

VFDs contain various sensitive electronic components such as transistors, capacitors, and diodes. These components can fail due to power surges, electrical shorts, or simply wear over time. When one component fails, it can cause a chain reaction that leads to complete VFD malfunction.

Voltage Spikes

Voltage spikes, often caused by unstable power supplies or lightning strikes, can damage the internal components of a VFD. These spikes can lead to insulation breakdown, component failure, or even total VFD destruction in severe cases.

Improper Wiring and Installation

Improper installation, such as incorrect wiring or poor grounding, can lead to VFD failures. Issues with wiring can cause short circuits, electrical noise, or grounding problems, all of which can shorten the lifespan of the VFD.

Contamination

Dust, dirt, moisture, and other contaminants can infiltrate a VFD, especially if the environment is not clean or if the drive is not properly enclosed. Contamination can cause electrical shorts or overheating.

Lack of Maintenance

Like any other piece of equipment, VFDs require regular maintenance. Neglecting to clean filters, check cooling systems, and inspect wiring can lead to preventable failures.

Cost-Effective Repair Strategies

Repairing a faulty VFD can be far more economical than replacing the unit, particularly when implementing the right strategies. Below are several cost-effective VFD repair approaches that can reduce downtime, extend the lifespan of the drive, and save on operational costs.

Conduct a Thorough Diagnosis

The first step in any repair process is to conduct a comprehensive diagnosis of the VFD. A detailed inspection should include checking for physical damage, testing electrical components, and monitoring the operation of the VFD under load. Using diagnostic tools such as oscilloscopes and multimeters can help pinpoint the exact cause of the failure.

By understanding the root cause of the problem, operators can avoid unnecessary repairs and focus on fixing the issue that caused the failure in the first place. This not only saves time but also reduces the costs associated with replacing parts that are still functional.

Prioritize Repair Over Replacement

In many cases, repairing a VFD is far more cost-effective than replacing it with a new one. For example, if only a few components like capacitors or transistors have failed, replacing these parts can restore the VFD to full functionality at a fraction of the cost of a new drive.

Some industrial operators have in-house technicians who can handle minor repairs, such as replacing fuses or capacitors. For more complex repairs, partnering with a trusted VFD repair specialist can ensure the job is done correctly without the expense of purchasing a brand-new unit.

Implement Preventative Maintenance Programs

Preventative maintenance is one of the most effective ways to reduce VFD repair costs. Regular maintenance can catch small issues before they escalate into major problems, extending the life of the VFD and minimizing downtime.

A comprehensive maintenance program should include cleaning the unit, checking cooling systems, inspecting wiring, and ensuring that the VFD is operating within its specified parameters. Some key maintenance tasks include:

- Filter cleaning: Dust and dirt can block airflow, causing overheating.

- Fan inspection: Cooling fans should be checked regularly to ensure they are working correctly.

- Component testing: Periodically testing capacitors and other key components can identify early signs of failure.

By investing in a good maintenance program, operators can avoid frequent breakdowns and extend the overall life of their VFDs.

Stock Spare Parts

Having a supply of common VFD spare parts on hand can save both time and money when a repair is needed. Some components, such as fuses, fans, and capacitors, tend to fail more frequently than others. By stocking these parts, operators can avoid the long lead times often associated with ordering replacements and reduce downtime during repairs.

In addition to having spare parts on hand, it is also beneficial to have repair manuals and documentation available for the specific VFD models in use. This allows in-house technicians to perform basic repairs without the need for external assistance.

Utilize Refurbished Components

Using refurbished or reconditioned components can be a highly cost-effective way to repair VFDs. Many repair shops offer high-quality refurbished parts that are tested and certified to meet original equipment manufacturer (OEM) standards.

Refurbished components are often available at a fraction of the cost of new parts, making them a viable option for budget-conscious operations. However, it is crucial to work with reputable suppliers to ensure the quality and reliability of the refurbished components.

Consider Outsourcing Repairs to Specialized Technicians

While in-house technicians can handle basic repairs, some VFD issues require specialized expertise. In these cases, outsourcing repairs to experienced technicians or repair shops can be more cost-effective than attempting to fix the problem internally.

Specialized repair companies often have the tools, training, and experience needed to address complex issues, ensuring that the VFD is repaired correctly the first time. Moreover, many repair shops offer warranties on their work, providing additional peace of mind.

When selecting a repair service, it is essential to choose a company with a solid reputation and experience in handling the specific VFD model in use. This ensures that repairs are completed efficiently and to a high standard.

Utilize Diagnostic Software for Remote Monitoring

Remote monitoring software allows operators to track the performance of their VFDs in real-time, identifying potential issues before they lead to failure. This proactive approach can help reduce repair costs by addressing problems early on.

Many modern VFDs come equipped with diagnostic tools that can detect issues such as overheating, voltage irregularities, and component wear. By integrating these tools with remote monitoring systems, operators can receive alerts when a VFD is operating outside of its optimal range, allowing them to take corrective action before a failure occurs.

Train Personnel on Proper VFD Handling and Maintenance

Another way to reduce VFD repair costs is by ensuring that personnel are properly trained on how to handle and maintain these devices. Training should cover topics such as correct installation procedures, regular maintenance tasks, and how to identify signs of potential failure.

Well-trained employees are less likely to make mistakes that lead to premature VFD failure, and they are more likely to catch small issues before they escalate. Investing in employee training can pay off in the long run by reducing the need for costly repairs and replacements.

Develop a VFD Failure Response Plan

Having a failure response plan in place can minimize downtime and repair costs when a VFD does fail. The plan should outline the steps to take when a failure occurs, including identifying the problem, determining whether an in-house technician can handle the repair, and contacting external repair services if necessary.

A well-structured response plan can help ensure that repairs are completed quickly and efficiently, reducing the impact on production and minimizing the associated costs.

Plan for Upgrades and End-of-Life Management

While repairing a VFD can be cost-effective, there comes a point where it is no longer feasible to continue repairing an aging drive. Planning for the end-of-life of a VFD and budgeting for upgrades can help avoid costly breakdowns and unscheduled downtime.

In some cases, upgrading to a newer, more efficient VFD can provide long-term cost savings through improved performance and energy efficiency. Planning for these upgrades as part of a broader asset management strategy ensures that they can be implemented smoothly without disrupting operations.

Conclusion

Effective VFD repair strategies are essential for maintaining operational efficiency and controlling costs in industrial settings. By prioritizing repairs over replacements, implementing preventative maintenance programs, and training personnel, operators can extend the life of their VFDs and avoid costly downtime. Additionally, utilizing diagnostic tools, outsourcing complex repairs to specialists, and stocking spare parts can further enhance the cost-effectiveness of VFD repairs.

With the right approach, industrial operators can keep their systems running smoothly, minimize repair costs, and maximize the lifespan of their VFDs, ensuring that they continue to deliver value for years to come.