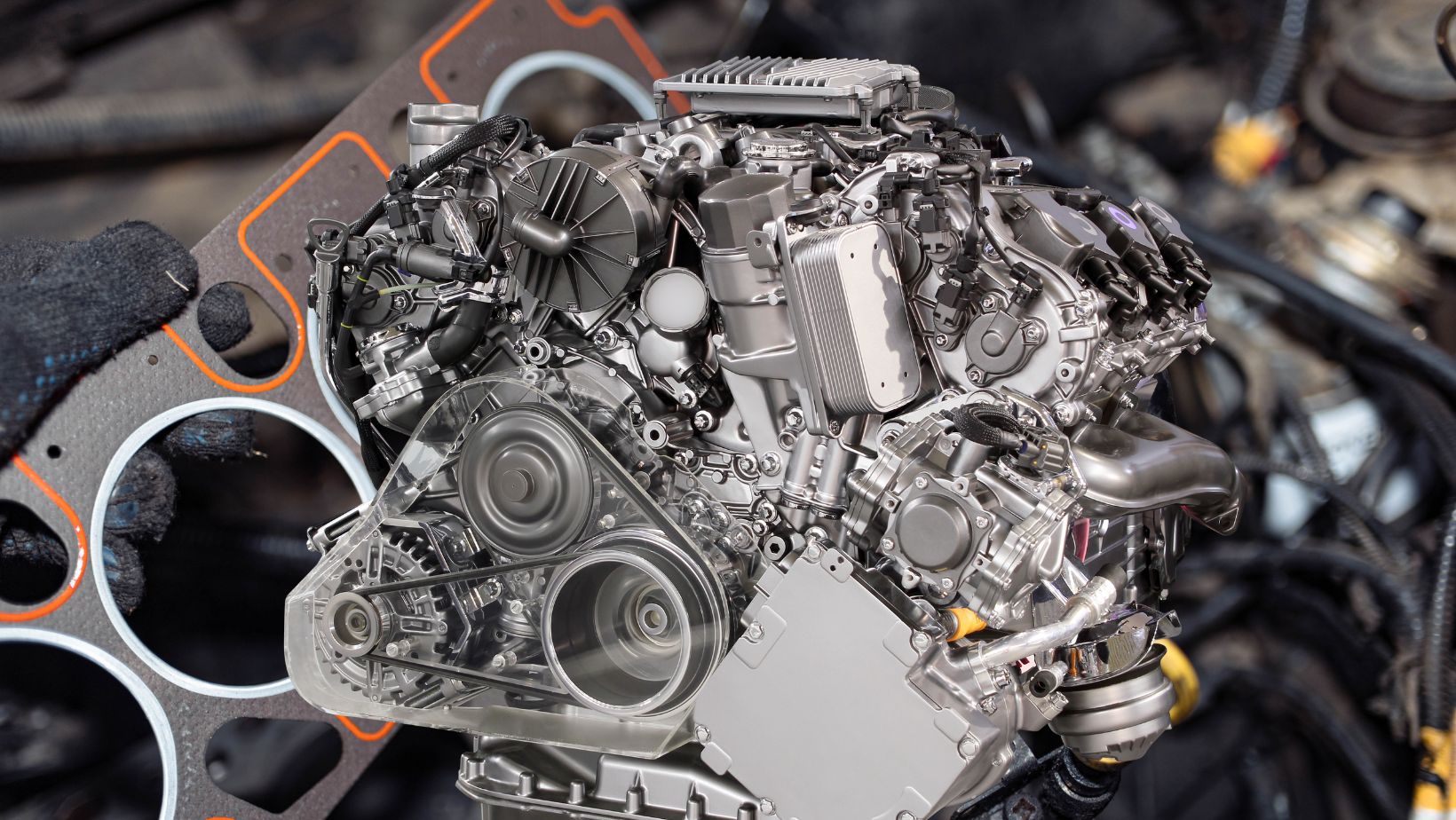

In the world of engine building, every component plays a crucial role, but few are as critical as the engine connecting rod. These unassuming pieces of metal are responsible for transferring the immense forces generated by combustion to the crankshaft, effectively turning explosions into motion.

This guide explores the intricacies of connecting rods, their importance, and how to select the right ones for an engine build.

What Are Connecting Rods?

Before delving into selection criteria, it’s essential to understand what connecting rods are. Connecting rods are the components that link the pistons to the crankshaft in an internal combustion engine.

They serve as the vital link that transfers the reciprocating motion of the pistons into the rotational motion of the crankshaft. This fundamental design is so integral to engine function that many refer to modern internal combustion engines as connecting rod engines, highlighting the crucial role these components play.

A typical engine connecting rod consists of three main parts:

- The small end, which attaches to the piston pin

- The big end, which connects to the crankshaft

- The beam, which is the main body of the rod connecting the two ends

The design and material of these components can significantly impact an engine’s performance, reliability, and longevity.

The Importance of Proper Connecting Rod Selection

Choosing the right connecting rods for an engine build is crucial for several reasons:

- Strength: Engine connecting rods must withstand enormous forces, especially in high-performance engines.

- Weight: Lighter rods can help reduce reciprocating mass, allowing for higher RPMs.

- Durability: The right rods can significantly extend engine life.

- Performance: Properly chosen rods can help maximize power output and efficiency.

Understanding what connecting rods are and their function is key to appreciating their importance in engine design and performance.

Factors to Consider When Selecting Connecting Rods

Material

Connecting rods can be manufactured from various materials, each with its own advantages and disadvantages:

- Steel: Strong and affordable, suitable for most applications.

- Forged Steel: Stronger than cast steel, ideal for high-performance builds.

- Aluminum: Lightweight but less durable, typically used in racing applications.

- Titanium: Extremely light and strong but very expensive.

The choice of material depends on the engine’s intended use and budget constraints.

Design

The design of the connecting rod can impact its strength and weight. Common designs include:

- I-beam: The traditional design offers a good balance of strength and weight.

- H-beam: Stronger than I-beam, often used in high-performance applications.

- A-beam: A newer design that offers strength comparable to H-beam but with less weight.

Length

The length of the connecting rod affects the engine’s stroke and compression ratio.

Longer rods generally produce less side thrust on the cylinder walls but may require custom pistons or other modifications.

Weight

Lighter connecting rods allow for higher RPMs and quicker acceleration, but they may sacrifice some durability. It’s important to balance weight reduction with strength requirements.

Big End Bearing Style

There are two main types of big-end bearings:

- Press fit: More common in OEM applications, these require specialized equipment to install.

- Floating pin: Easier to assemble and disassemble, often used in racing engines.

Manufacturing Process

Connecting rods can be:

- Cast: Cheapest option, suitable for stock replacements.

- Forged: Stronger than cast, good for performance builds.

- Billet: Machined from a solid piece of metal, offering the highest strength but also the highest cost.

Matching Connecting Rods to Specific Engines

When selecting connecting rods, it’s crucial to consider the engine’s specific needs. Factors to keep in mind include:

Engine Type

Different engine types have different requirements. For example:

- High-revving motorcycle engines might benefit from lightweight, high-strength rods.

- Heavy-duty diesel engines need extremely strong, durable rods to handle high compression ratios.

- Everyday passenger car engines typically do well with standard steel rods.

Horsepower Goals

The more power an engine is designed to produce, the stronger its rods need to be. High-horsepower engines often require upgraded forged or billet rods.

RPM Range

Engines designed for high RPMs benefit from lighter rods, which can help reduce reciprocating mass and allow for quicker revving.

Budget

While high-end rods can offer superior performance, it’s important to balance performance with cost. For many builds, a good set of forged steel rods will provide excellent performance at a reasonable price.

The Piston Connecting Rod Relationship

When choosing connecting rods, it’s important to consider their relationship with the pistons. The piston connecting rod assembly is a crucial part of the engine’s rotating assembly. Key considerations include:

- Rod Ratio: This is the ratio of the rod length to the stroke. A higher rod ratio generally results in less side thrust on the cylinder walls.

- Piston Pin Diameter: The small end of the rod must match the diameter of the piston pins.

- Total Weight: The combined weight of the piston connecting rod assembly affects the engine’s balance and maximum RPM.

- Clearances: Adequate clearance between the rod and the piston at all points in the stroke is essential.

Installation and Maintenance

Proper installation and maintenance of connecting rods are crucial for engine performance and longevity. Best practices include:

- Following manufacturer’s torque specifications when tightening rod bolts.

- Quality assembly lube is used on all bearing surfaces during installation.

- Checking and maintaining proper bearing clearances.

- Magnafluxing rods to check for cracks or other damage if reusing them.

- Replacing rod bolts with new ones during a rebuild, especially in high-performance applications.

- Regularly checking oil pressure and quality to ensure proper lubrication of the rod bearings.

The Future of Connecting Rod Technology

As engine technology advances, so does connecting rod design. Emerging trends include:

- New materials: Research into new alloys and composites that offer better strength-to-weight ratios.

- Advanced manufacturing techniques: 3D printing and other cutting-edge methods may allow for more complex, optimized rod designs.

- Integrated sensors: Development of high-tech rods with built-in sensors to monitor bearing wear and other factors in real time.

- Variable-length rods: Experimental designs that could allow for on-the-fly changes to an engine’s stroke and compression ratio.

Conclusion:

Choosing the right connecting rods is a critical aspect of any engine build. By considering factors such as material, design, weight, and specific engine needs, builders can select rods that will optimize engine performance while ensuring reliability and longevity.

The engine connecting rod relationship is at the heart of an engine’s operation. These components play a vital role in transforming the power of combustion into mechanical energy that propels a vehicle.

Whether building a high-revving race engine, a torque-monster diesel, or refreshing a daily driver, taking the time to choose the right connecting rods can yield significant benefits in performance and reliability.

Understanding what connecting rods are and their critical role in engine function is essential for any serious engine builder or enthusiast.

These critical components should never be overlooked in any engine build. By carefully selecting the right connecting rods, engine builders can ensure they’re creating a powerplant that’s not only powerful but also reliable and long-lasting.